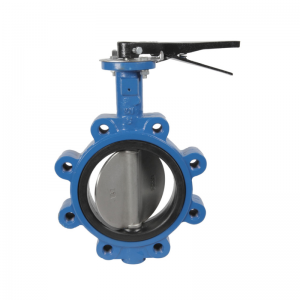

Wafer Type High Performance Double Offset Butterfly Valve

Wafer Type High Performance Double Offset Butterfly Valve

BAFAW high performance butterfly valve is an innovative double offset design product with advanced world leading technology. This butterfly valve has a unique structure with ultra reliable sealing performance, wide working conditions and low operation torque.

Main product features

| 1. One million operations |

| 2. Zero leakage in both direction |

| 3. Easy maintenance |

| 4. Independent and internal test |

Product Description

| Name | High performance butterfly valve |

| Design | API 609/ASME B16.34 |

| End Connection | Wafer/Lug/Double flanged |

| Operation | Manual/Pneumatic/Electric |

| Size Range | NPS 2"-60"(DN50-DN1500) |

| Pressure Rating | ASME Class150-300-600(PN16-PN25-PN40) |

| Body Material | Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel |

| Seat Material | PTFE, RPTFE, PPL |

| Temperature | -29℃ to 250℃ |

Application: Petrochemical, Water treatment, PSA, Power plant, Dry air compressor etc.

Our Company

We devote to the best quality products, the honest and trustworthy rules, competitive price, the strict quality testing of each production steps to guarantee the customers satisfaction, to setting up the good enterprise image all over the world, we will adhere to the “Quality is our life, Honest and trustworthy is our basis, Competitive price is our advantage” as enterprise guidelines.

Our Company

The wafer type soft sealing butterfly valve can be used for opening and closing or regulating medium flow of clean pipelines such as food, medicine and chemical industry, industrial environmental protection, water treatment, high-rise buildings and water supply and drainage pipelines.

The butterfly plate of the wafer soft seal butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis with a rotation angle of 0 ° ~ 90 °. When it rotates to 90 °, the valve is fully open.

characteristic

Small and light, easy to disassemble and repair, and can be installed at any position.

The structure is simple and compact, and the 90 ° rotary opening and closing is fast.

Small operating torque, labor-saving and light.

The flow characteristics tend to be linear and the regulation performance is good.

The number of opening and closing tests is up to tens of thousands, and the service life is long.

Complete sealing is achieved and the gas test leakage is zero.

Select different component materials, which can be applied to a variety of media.